Rice Milling Machine: The Heart of Modern Rice Production

Rice, a cornerstone of global diets, undergoes an intricate transformation from a raw paddy grain to the polished, edible rice we consume. This complex process is orchestrated by the Rice Milling Machine, an indispensable piece of equipment for farmers, millers, and food processors worldwide. Far from being a single unit, a modern rice milling system comprises a series of specialized machines, each playing a crucial role in delivering high-quality rice to consumers.

At Ricetec Machinery, we specialize in providing advanced and reliable rice processing solutions. With over two decades of experience, we understand the nuances of the rice industry and the critical role that efficient machinery plays in maximizing yield, minimizing waste, and ensuring superior product quality.

The Journey of Paddy Through a Rice Milling Machine

The goal of a rice milling machine is to efficiently remove the husk (outer protective layer) and the bran (inner layers) from the paddy grain, while minimizing breakage of the rice kernel. This multi-stage process ensures that the final product is clean, polished, and ready for consumption.

Here’s a breakdown of the typical stages and the specific rice milling machines involved:

1. Pre-Cleaning: Setting the Stage for Purity

Raw paddy, fresh from the fields, often contains impurities like straw, dust, stones, and other foreign materials. The first step in any efficient rice mill is to remove these contaminants using a pre-cleaner.

- Function: To separate larger impurities from the paddy.

- Machine Type: Vibrating screens, aspiration channels, or drum cleaners.

- Importance: Protects downstream machinery from damage and ensures a cleaner input for subsequent processing.

Following pre-cleaning, a de-stoner is vital for removing stones and heavy particles that may have passed through the pre-cleaner. These machines use a combination of vibration and air currents to separate materials based on their specific gravity.

2. De-husking (Shelling): Revealing the Brown Rice

Once cleaned, the paddy moves to the de-husking stage, where the tough outer husk is removed. This process yields brown rice.

- Function: To efficiently remove the husk without damaging the rice kernel.

- Machine Type: Rubber roller hullers are the most common and effective type. They use two rubber rollers rotating at different speeds to gently strip off the husk.

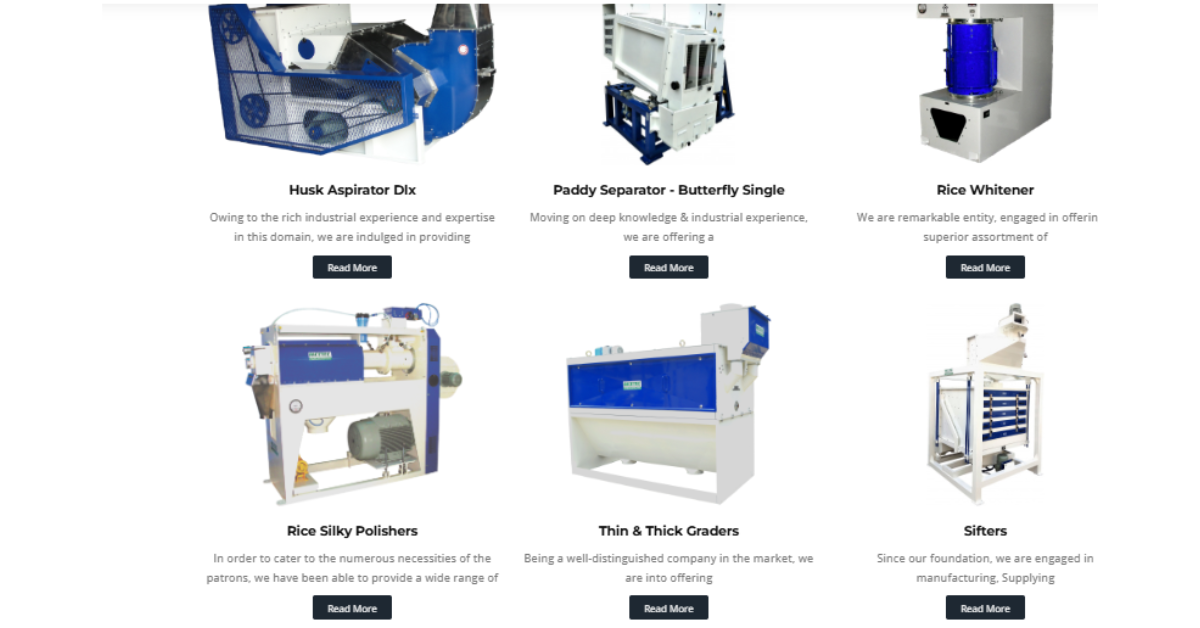

- Husk Aspirator: After de-husking, a husk aspirator uses suction to separate the lightweight husks from the heavier brown rice kernels. The husks can often be used as fuel or for other industrial applications.

3. Paddy Separation: Distinguishing Un-husked Grains

Even with highly efficient hullers, some paddy grains may remain un-husked. A paddy separator is crucial for identifying and separating these un-husked grains from the brown rice.

- Function: To separate un-husked paddy from brown rice based on differences in density and friction.

- Machine Type: Often consists of trays or vibrating tables that stratify the grains, allowing for separation.

- Importance: Ensures that only de-husked rice proceeds to the whitening stage, preventing damage to whitener components and maintaining product consistency.

4. Whitening (Polishing): Achieving the Desired Finish

The brown rice, while nutritious, still retains its bran layers, which give it a brownish color. For white rice, these bran layers are removed through a process called whitening or polishing.

- Function: To remove the bran layers from the brown rice.

- Machine Type:

- Rice Whiteners (Abrasive or Friction Type): These machines use abrasive rollers or friction to gently remove the bran. The degree of whitening can be adjusted.

- Silky Rice Polishers: Used after initial whitening, these machines provide a smoother, shinier finish to the rice, enhancing its visual appeal. They often use a fine spray of water to reduce friction and heat.

5. Grading and Sifting: Ensuring Uniformity

After polishing, the rice kernels need to be sorted and graded based on size, shape, and quality to meet market standards and consumer preferences.

- Function: To separate whole grains from broken grains, immature kernels, and other remaining impurities.

- Machine Type:

- Rice Sifters/Multi-deck Sifters: These machines use multiple vibrating screens with different mesh sizes to separate rice into various grades (e.g., head rice, large brokens, small brokens).

- Length Graders: Specifically designed to separate rice grains based on their length, crucial for achieving consistent grain sizes.

- Thickness Graders: Used to separate grains based on their thickness, removing undersized or immature grains.

6. Color Sorting: The Final Touch of Perfection

For premium rice products, color sorters are employed as the ultimate quality control measure.

- Function: To detect and remove discolored grains, foreign particles, and other subtle defects that might not be visible to the human eye or removed by mechanical graders.

- Machine Type: Advanced optical sorting machines that use cameras and air jets to identify and eject defective grains.

- Importance: Ensures exceptionally high purity and visual quality of the final product.

7. Ancillary Equipment and Support Systems

A complete rice milling plant also relies on various supporting machines and systems:

- Bucket Elevators: For efficient vertical transport of grains between different stages of the process.

- Blowers and Cyclones: For effective dust collection and ventilation, maintaining a clean and safe working environment.

- Control Panels and Automation: Centralized systems for monitoring, controlling, and optimizing the entire milling process, reducing manual intervention and ensuring consistency.

- Bagging and Packaging Machines: For efficient weighing, filling, and sealing of milled rice into bags, ready for distribution.

Benefits of Modern Rice Milling Machines

Investing in modern rice milling machines offers numerous advantages for millers and agricultural businesses:

- Increased Efficiency and Productivity: Automated processes and higher capacities lead to significantly faster processing times and greater output.

- Improved Rice Quality: Precision machinery results in uniformly milled, polished, and pure rice with minimal broken grains, enhancing market value.

- Reduced Post-Harvest Losses: Effective cleaning, de-hulling, and sorting minimize grain wastage, contributing to higher yields and profitability.

- Lower Operational Costs: Energy-efficient designs and reduced labor requirements translate to significant long-term savings.

- Enhanced Food Safety: Thorough cleaning and sorting remove impurities and contaminants, ensuring a safe and hygienic food product.

- Versatility: Many modern machines can be adjusted to process different varieties of paddy and produce various grades of rice to meet diverse market demands.

- Sustainability: Reduced energy consumption and better management of by-products (like husks used as fuel) contribute to more environmentally friendly operations.

Choosing the Right Rice Milling Machine

Selecting the appropriate rice milling machine or a complete milling plant requires careful consideration of several factors:

- Capacity: Determine your required processing volume (e.g., tons per hour/day).

- Rice Variety: Different rice types may require specific machine configurations.

- Desired Output Quality: The level of whiteness, polish, and purity you aim for.

- Budget: Initial investment costs and long-term operational expenses.

- Space Availability: The physical footprint of the machinery.

- After-Sales Support: The availability of spare parts, technical assistance, and maintenance services.

At Ricetec Machinery, we pride ourselves on offering a comprehensive range of rice milling machines, from individual units to complete, fully automated plants. Our expertise, commitment to quality, and extensive after-sales support ensure that our clients receive the best possible solutions to meet their rice processing needs, contributing to a robust and efficient global food supply chain.